Atomic layer–deposited nanostructures and their applications in energy storage and sensing

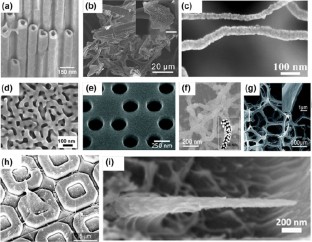

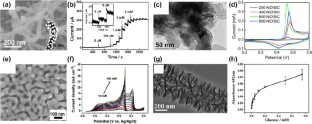

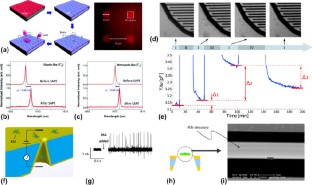

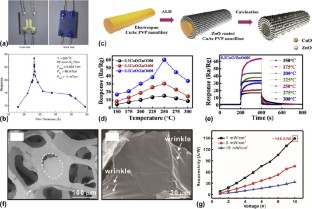

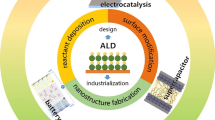

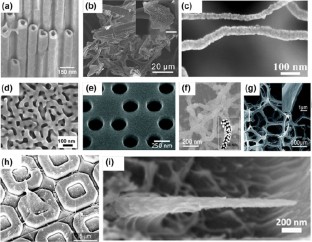

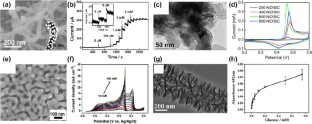

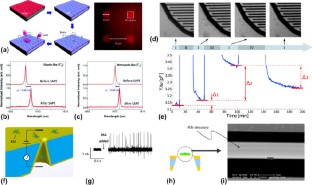

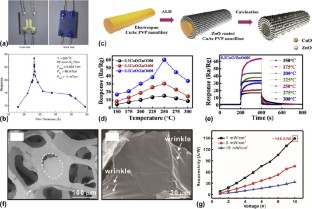

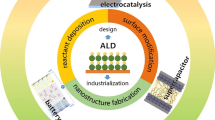

Nanostructures are considered to have great potential and are widely used in energy storage and sensing devices, and atomic layer deposition (ALD) is of great help for better nanostructure fabrications. ALD can help to preserve the original properties of materials, and, meanwhile, the excellent film quality, nanoscale precise thickness control, and high conformality also play important role in fabrication process. To enhance the performance of energy storage and sensor devices, ALD has been used in directly fabricating active nanostructures, depositing protective passivation layers, etc. ALD is a convenient technique which has been widely engaged in energy-related fields including electrochemical conversion and storage, as well as in sensor and biosensors. The related research interest is increasing significantly. In this review, we summarize some of the latest works on ALD for batteries, supercapacitors, and sensors, and demonstrate the benefits of ALD comprehensively. In these devices, different materials are deposited by ALD under different conditions to achieve better battery performance, higher supercapacitor capacitance, and higher sensitivity. This review fully presents the strengths of ALD and its application in energy storage and sensing devices and proposes the future prospects for this rapidly developing technology.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

Instant access to the full article PDF.

Rent this article via DeepDyve

Similar content being viewed by others

Atomic Layer Deposition for Electrochemical Energy: from Design to Industrialization

Article 24 November 2022

Nanogenerator-Based Self-Charging Energy Storage Devices

Article Open access 09 March 2019

Electrochemically Fabricated Nanostructures in Energy Storage and Conversion Applications

Chapter © 2016

References

- Z. Zhao, S.L. Liu, J.X. Zhu, J.S. Xu, L. Li, Z.Q. Huang, C. Zhang, and T.X. Liu: Hierarchical nanostructures of nitrogen-doped porous carbon polyhedrons confined in carbon nanosheets for high-performance supercapacitors. ACS Appl. Mater. Interfaces10, 19871 (2018). ArticleCASGoogle Scholar

- B.Y. Lee, D.H. Kim, J. Park, K-I. Park, K.J. Lee, and C.K. Jeong: Modulation of surface physics and chemistry in triboelectric energy harvesting technologies. Sci. Technol. Adv. Mater.20, 758 (2019). ArticleCASGoogle Scholar

- G.S. Huang and Y.F. Mei: Assembly and self-assembly of nanomembrane materials-from 2D to 3D. Small14, 1703665 (2018). ArticleCASGoogle Scholar

- M. Liu, B. Liu, Q.Q. Liu, K.K. Du, Z.F. Wang, and N.Y. He: Nanomaterial-induced ferroptosis for cancer specific therapy. Coord. Chem. Rev.382, 160 (2019). ArticleCASGoogle Scholar

- H.Y. Jin, C.X. Guo, X. Liu, J.L. Liu, A. Vasileff, Y. Jiao, Y. Zheng, and S.Z. Qiao: Emerging two-dimensional nanomaterials for electrocatalysis. Chem. Rev.118, 6337 (2018). ArticleCASGoogle Scholar

- M. Huang, F. Cavallo, F. Liu, and M.G. Lagally: Nanomechanical architecture of semiconductor nanomembranes. Nanoscale3, 96 (2011). ArticleCASGoogle Scholar

- M.B. Zheng, H. Tang, L.L. Li, Q. Hu, L. Zhang, H.G. Xue, and H. Pang: Hierarchically nanostructured transition metal oxides for lithium-ion batteries. Adv. Sci.5, 1700592 (2018). ArticleCASGoogle Scholar

- B. Fang, J.H. Kim, M.S. Kim, and J.S. Yu: Hierarchical nanostructured carbons with meso-macroporosity: Design, characterization, and applications. Acc. Chem. Res.46, 1397 (2013). ArticleCASGoogle Scholar

- S. Ding, D. Zhang, J.S. Chen, and X.W. Lou: Facile synthesis of hierarchical MoS2 microspheres composed of few-layered nanosheets and their lithium storage properties. Nanoscale4, 95 (2012). ArticleCASGoogle Scholar

- M. Radovic, G. Dubourg, Z. Dohcevic-Mitrovic, B. Stojadinovic, J. Vukmirovic, N. Samardzic, and M. Bokorov: SnO2 nanosheets with multifunctional properties for flexible gas-sensors and UVA light detectors. J. Phys. D Appl. Phys.52, 385305 (2019). ArticleCASGoogle Scholar

- S. Janghela, S. Devi, N. Kambo, D. Roy, K. Mukhopadhyay, and N.E. Prasad: Microphase separation in oriented polymeric chains at the surface of nanomaterials during nanofiber formation. Soft Matter15, 6811 (2019). ArticleCASGoogle Scholar

- Y. Cheng, Y. Chang, Y.L. Feng, H. Jian, X.Q. Wu, R.X. Zheng, L. Wang, X.M. Ma, K.Q. Xu, P.P. Song, Y.J. Wang, and H.Y. Zhang: Hierarchical acceleration of wound healing through intelligent nanosystem to promote multiple stages. ACS Appl. Mater. Interfaces11, 33725 (2019). ArticleCASGoogle Scholar

- B.M. Abu-Zied and K.A. Alamry: Green synthesis of 3D hierarchical nanostructured Co3O4/carbon catalysts for the application in sodium borohydride hydrolysis. J. Alloys Compd.798, 820 (2019). ArticleCASGoogle Scholar

- W.T. Zhu, H.H. Chen, J.W. Yang, W.X. Cai, Z.Q. Bao, and X.F. Zhou: One-pot fabrication of TiO2 rutile nanorods/anatase nanoparticles: Mixed crystal phase and morphology-control for enhanced photovoltaic performance. J. Nanosci. Nanotechnol.19, 7714 (2019). ArticleCASGoogle Scholar

- M.A. Pimenta, G. Dresselhaus, M.S. Dresselhaus, L.G. Cancado, A. Jorio, and R. Saito: Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys.9, 1276 (2007). ArticleCASGoogle Scholar

- P. Dai, Y. Jiao, H.L. Ma, X.M. Zeng, Y.J. Lu, L.C. Wang, M. Bao, and M.L. Zhai: Radiation synthesis of polysilane-modified graphene oxide for improving thermal conductivity and mechanical properties of silicone rubber. J. Appl. Polym. Sci.136, 47776 (2019). ArticleCASGoogle Scholar

- S. Linic, P. Christopher, and D.B. Ingram: Plasmonic-metal nanostructures for efficient conversion of solar to chemical energy. Nat. Mater.10, 911 (2011). ArticleCASGoogle Scholar

- D. Li, M.B. Mueller, S. Gilje, R.B. Kaner, and G.G. Wallace: Processable aqueous dispersions of graphene nanosheets. Nat. Nanotechnol.3, 101 (2008). ArticleCASGoogle Scholar

- P.O. Oviroh, R. Akbarzadeh, D. Pan, R.A.M. Coetzee, and T.C. Jen: New development of atomic layer deposition: Processes, methods and applications. Sci. Technol. Adv. Mater.20, 465 (2019). ArticleGoogle Scholar

- A. Sutka, M. Jarvekulg, and K.A. Gross: Photocatalytic nanoheterostructures and chemically bonded junctions made by solution-based approaches. Crit. Rev. Solid State Mater. Sci.44, 239 (2019). ArticleCASGoogle Scholar

- Y. Zhang, Y. Yang, H. Sun, and J. Wang: Synthesis of TiB2 powders with hexagonal morphology by sol–gel method. J. Nanosci. Nanotechnol.19, 7886 (2019). ArticleCASGoogle Scholar

- R. Yang, Z. Gong, X. Zhang, and L. Que: Single-walled carbon nanotubes (SWCNTs) and poly(3,4-ethylenedioxythiophene) nanocomposite microwire-based electronic biosensor fabricated by microlithography and layer-by-layer nanoassembly. J. Nanosci. Nanotechnol.19, 7591 (2019). ArticleCASGoogle Scholar

- M. Nazari, S. Kashanian, and R. Mohammadi: Electrodeposition of anionic, cationic and nonionic surfactants and gold nanoparticles onto glassy carbon electrode for catechol detection. J. Nanoanalysis6, 48 (2019). Google Scholar

- O.M. Dawood, R.K. Gupta, U. Monteverde, F.H. Alqahtani, H-Y. Kim, J. Sexton, R.J. Young, M. Missous, and M.A. Migliorato: Dynamic modulation of the Fermi energy in suspended graphene backgated devices. Sci. Technol. Adv. Mater.20, 568 (2019). ArticleCASGoogle Scholar

- M.C. Tseng, D.S. Wuu, C.L. Chen, H.Y. Lee, C.Y. Chien, P.L. Liu, and R.H. Horng: Characteristics of atomic layer deposition-grown zinc oxide thin film with and without aluminum. Appl. Surf. Sci.491, 535 (2019). ArticleCASGoogle Scholar

- S. Lee, Y. Lee, J. Park, W. Yu, G.Y. Cho, Y. Kim, and S.W. Cha: Effect of plasma-enhanced atomic layer deposited YSZ inter-layer on cathode interface of GDC electrolyte in thin film solid oxide fuel cells. Renew. Energ.144, 123 (2019). ArticleCASGoogle Scholar

- Y. Kim, M. Chang, S. Cho, M. Kim, H. Kim, E. Choi, H. Ko, J. Hwang, and B. Park: Formation of a functional homo-junction interface through ZnO atomic layer passivation: Enhancement of carrier mobility and threshold voltage in a ZnO nanocrystal field effect transistor. J. Alloy. Compd.804, 213 (2019). ArticleCASGoogle Scholar

- S. Zhu, J. Liu, and J. Sun: Precise growth of Al2O3/SnO2/CNTs composites by a two-step atomic layer deposition and their application as an improved anode for lithium ion batteries. Electrochim. Acta319, 490 (2019). ArticleCASGoogle Scholar

- R. Solanki, J. Huo, J.L. Freeouf, and B. Miner: Atomic layer deposition of ZnSe/CdSe superlattice nanowires. Appl. Phy. Lett.81, 3864 (2002). ArticleCASGoogle Scholar

- B. Ahmed, C. Xia, and H.N. Alshareef: Electrode surface engineering by atomic layer deposition: A promising pathway toward better energy storage. Nano Today11, 250 (2016). ArticleCASGoogle Scholar

- D. Chen, Z. Kang, H. Hirahara, S. Aisawa, and W. Li: Adsorption behaviors of deposition-targeted metallic ions onto thiol-containing silane modified liquid crystal polymer surfaces. Appl. Surf. Sci.479, 368 (2019). ArticleCASGoogle Scholar

- M. Knez, A. Kadri, C. Wege, U. Gosele, H. Jeske, and K. Nielsch: Atomic layer deposition on biological macromolecules: Metal oxide coating of tobacco mosaic virus and ferritin. Nano Lett.6, 1172 (2006). ArticleCASGoogle Scholar

- X. Li, X. Meng, J. Liu, D. Geng, Y. Zhang, M.N. Banis, Y. Li, J. Yang, R. Li, X. Sun, M. Cai, and M.W. Verbrugge: Tin oxide with controlled morphology and crystallinity by atomic layer deposition onto graphene nanosheets for enhanced lithium storage. Adv. Funct. Mater.22, 1647 (2012). ArticleCASGoogle Scholar

- Y.S. Jung, A.S. Cavanagh, L.A. Riley, S.H. Kang, A.C. Dillon, M.D. Groner, S.M. George, and S.H. Lee: Ultrathin direct atomic layer deposition on composite electrodes for highly durable and safe Li-ion batteries. Adv. Mater.22, 2172 (2010). ArticleCASGoogle Scholar

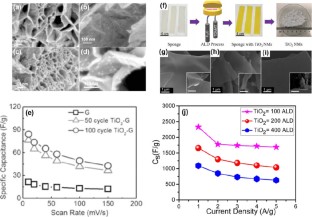

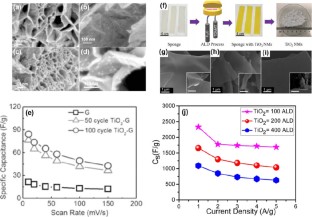

- X. Sun, M. Xie, G. Wang, H. Sun, A.S. Cavanagh, J.J. Travis, S.M. George, and J. Lian: Atomic layer deposition of TiO2 on graphene for supercapacitors. J. Electrochem. Soc.159, A364 (2012). ArticleCASGoogle Scholar

- C. Guan, X. Xia, N. Meng, Z. Zeng, X. Cao, C. Soci, H. Zhang, and H.J. Fan: Hollow core–shell nanostructure supercapacitor electrodes: Gap matters. Energy Environ. Sci.5, 9085 (2012). ArticleCASGoogle Scholar

- S. Boukhalfa, K. Evanoff, and G. Yushin: Atomic layer deposition of vanadium oxide on carbon nanotubes for high-power supercapacitor electrodes. Energy Environ. Sci.5, 6872 (2012). ArticleCASGoogle Scholar

- A.M. van der Zande, P.Y. Huang, D.A. Chenet, T.C. Berkelbach, Y. You, G.H. Lee, T.F. Heinz, D.R. Reichman, D.A. Muller, and J.C. Hone: Grains and grain boundaries in highly crystalline monolayer molybdenum disulphide. Nat. Mater.12, 554 (2013). ArticleCASGoogle Scholar

- S. Hofmann, R. Sharma, C. Ducati, G. Du, C. Mattevi, C. Cepek, M. Cantoro, S. Pisana, A. Parvez, F. Cervantes-Sodi, A.C. Ferrari, R. Dunin-Borkowski, S. Lizzit, L. Petaccia, A. Goldoni, and J. Robertson: In situ observations of catalyst dynamics during surface-bound carbon nanotube nucleation. Nano Lett.7, 602 (2007). ArticleCASGoogle Scholar

- Z. Zhao, Z.W. Zhang, Y.T. Zhao, J.R. Liu, C. Liu, Z.J. Wang, G.F. Zheng, G.S. Huang, and Y.F. Mei: Atomic layer deposition inducing integration of Co, N codoped carbon sphere on 3D foam with hierarchically porous structures for flexible hydrogen producing device. Adv. Funct. Mater. 1906365 (2019). Google Scholar

- S. Ratan, C. Kumar, A. Kumar, D.K. Jarwal, A.K. Mishra, R.K. Upadhyay, and S. Jit: Fabrication and characterization of a ZnO quantum dots-based metal-semiconductor-metal sensor for hydrogen gas. Nanotechnology30, 395501 (2019). ArticleCASGoogle Scholar

- M.L. Huang, Y.C. Chang, C.H. Chang, Y.J. Lee, P. Chang, J. Kwo, T.B. Wu, and M. Hong: Surface passivation of III–V compound semiconductors using atomic-layer-deposition-grown Al2O3. Appl. Phy. Lett.87, 252104 (2005). ArticleCASGoogle Scholar

- H.C.M. Knoops, M.E. Donders, L. Baggetto, M. Sanden, P.H.L. Notten, and W.M.M. Kessels: Atomic layer deposition for all-solid-state 3D-integrated batteries. ECS Trans.25, 333 (2009). ArticleCASGoogle Scholar

- M. Reghima, A. Akkari, C. Guasch, and N. Kamoun-Turki: Effect of indium doping on physical properties of nanocrystallized SnS zinc blend thin films grown by chemical bath deposition. J. Renew. Sustain. Ener.4, 011602 (2012). ArticleCASGoogle Scholar

- T.B. Nasr, N. Kamoun, and C. Guasch: Physical properties of ZnS thin films prepared by chemical bath deposition. Appl. Surf. Sci.254, 5039 (2008). ArticleCASGoogle Scholar

- K. Baek, C. Jin, J. Lee, B.Y. Jeong, W.I. Lee, and C. Lee: Structure and photoluminescence properties of ZnS nanowires sheathed with SnO2 by atomic layer deposition. J. Mater. Sci.45, 3851 (2010). ArticleCASGoogle Scholar

- S.M. George: Atomic layer deposition: An overview. Chem. Rev.110, 111 (2010). ArticleCASGoogle Scholar

- R.L. Puurunen: Surface chemistry of atomic layer deposition: A case study for the trimethylaluminum/water process. J. Appl. Phy.97, 121301 (2005). ArticleCASGoogle Scholar

- M.D. Groner, F.H. Fabreguette, J.W. Elam, and S.M. George: Low-temperature Al2O3 atomic layer deposition. Chem. Mater.16, 639 (2004). ArticleCASGoogle Scholar

- J.S. Wellings, N.B. Chaure, S.N. Heavens, and I.M. Dhannadasa: Growth and characterisation of electrodeposited ZnO thin films. Thin Solid Films516, 3893 (2008). ArticleCASGoogle Scholar

- M. Schreier, F. Heroguel, L. Steier, S. Ahmad, J.S. Luterbacher, M.T. Mayer, J. Luo, and M. Gratzel: Solar conversion of CO2 to CO using earth-abundant electrocatalysts prepared by atomic layer modification of CuO. Nat. Energy2, 17087 (2017). ArticleCASGoogle Scholar

- L. Niinisto, J. Paivasaari, J. Niinisto, M. Putkonen, and M. Nieminen: Advanced electronic and optoelectronic materials by atomic layer deposition: An overview with special emphasis on recent progress in processing of high-k dielectrics and other oxide materials. Phys. Status Solidi a201, 1443 (2004). ArticleCASGoogle Scholar

- C. Guan, X. Wang, Q. Zhang, Z. Fan, H. Zhang, and H.J. Fan: Highly stable and reversible lithium storage in SnO2 nanowires surface coated with a uniform hollow shell by atomic layer deposition. Nano Lett.14, 4852 (2014). ArticleCASGoogle Scholar

- H. Zhao, H. Gao, B. Li, Z. Song, T. Hu, and F. Liu: Atomic layer deposition of V2O5 on nitrogen-doped graphene as an anode for lithium-ion batteries. Mater. Lett.252, 215 (2019). ArticleCASGoogle Scholar

- Z. Szabo, J. Volk, Z.E. Horvath, Z. Medveczky, Z. Czigany, K. Vad, and Z. Baji: Atomic layer deposition and annealing of Ga doped ZnO films. Mater. Sci. Semi. Process.101, 95 (2019). ArticleCASGoogle Scholar

- T. Tynell and M. Karppinen: Atomic layer deposition of ZnO: A review. Semicond. Sci. Technol.29, 043001 (2014). ArticleCASGoogle Scholar

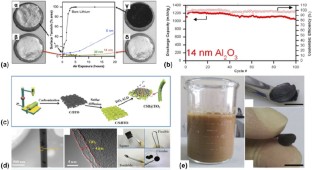

- A.C. Kozen, C.F. Lin, A.J. Pearse, M.A. Schroeder, X.G. Han, L.B. Hu, S.B. Lee, G.W. Rubloff, and M. Noked: Next-generation lithium metal anode engineering via atomic layer deposition. ACS Nano9, 5884 (2015). ArticleCASGoogle Scholar

- J. Robertson: High dielectric constant gate oxides for metal oxide Si transistors. Rep. Prog. Phys.69, 327 (2006). ArticleCASGoogle Scholar

- C. Park, J. Yoon, and E.L. Thomas: Enabling nanotechnology with self assembled block copolymer patterns. Polymer44, 6725 (2003). ArticleCASGoogle Scholar

- D. Golberg, Y. Bando, Y. Huang, T. Terao, M. Mitome, C. Tang, and C. Zhi: Boron nitride nanotubes and nanosheets. ACS Nano4, 2979 (2010). ArticleCASGoogle Scholar

- J.S. King, D. Heineman, E. Graugnard, and C.J. Summers: Atomic layer deposition in porous structures: 3D photonic crystals. Appl. Surf. Sci.244, 511 (2005). ArticleCASGoogle Scholar

- Y.J. Kwack and W.S. Choi: Chemical vapor deposition-free solution-processed synthesis method for two-dimensional MoS2 atomic layer films. Nanotechnology30, 38 (2019). ArticleCASGoogle Scholar

- M. Leskela and M. Ritala: Atomic layer deposition (ALD): From precursors to thin film structures. Thin Solid Films409, 138 (2002). ArticleCASGoogle Scholar

- E. Kim, Y. Vaynzof, A. Sepe, S. Guldin, M. Scherer, P. Cunha, S.V. Roth, and U. Steiner: Gyroid-structured 3D ZnO networks made by atomic layer deposition. Adv. Funct. Mater.24, 863 (2014). ArticleCASGoogle Scholar

- K.E. Gregorczyk, A.C. Kozen, X. Chen, M.A. Schroeder, M. Noked, A. Cao, L. Hu, and G.W. Rubloff: Fabrication of 3D core–shell multiwalled carbon nanotube@RuO2 lithium-ion battery electrodes through a RuO2 atomic layer deposition process. ACS Nano9, 464 (2015). ArticleCASGoogle Scholar

- C. Bae, H. Shin, and K. Nielsch: Surface modification and fabrication of 3D nanostructures by atomic layer deposition. MRS Bull.36, 887 (2011). ArticleCASGoogle Scholar

- X. Zhang, J. Zhao, A.V. Whitney, J.W. Elam, and R.P. Van Duyne: Ultrastable substrates for surface-enhanced Raman spectroscopy: Al2O3 overlayers fabricated by atomic layer deposition yield improved anthrax biomarker detection. J. Am. Chem. Soc.128, 10304 (2006). ArticleCASGoogle Scholar

- M. Ritala, K. Kukli, A. Rahtu, P.I. Raisanen, M. Leskela, T. Sajavaara, and J. Keinonen: Atomic layer deposition of oxide thin films with metal alkoxides as oxygen sources. Science288, 319 (2000). ArticleCASGoogle Scholar

- E. Bonera, G. Scarel, and M. Fanciulli: Structure evolution of atomic layer deposition grown ZrO2 films by deep-ultra-violet Raman and far-infrared spectroscopies. J. Non-Cryst. Solids322, 105 (2003). ArticleCASGoogle Scholar

- J. Johansson, J. Kostamo, M. Karppinen, and L. Niinisto: Growth of conductive copper sulfide thin films by atomic layer deposition. J. Mater. Chem.12, 1022 (2002). ArticleCASGoogle Scholar

- Q. Zhang, C.S. Dandeneau, X. Zhou, and G. Cao: ZnO nanostructures for dye-sensitized solar cells. Adv. Mater.21, 4087 (2009). ArticleCASGoogle Scholar

- X. Yang, A. Wolcott, G. Wang, A. Sobo, R.C. Fitzmorris, F. Qian, J.Z. Zhang, and Y. Li: Nitrogen-doped ZnO nanowire arrays for photoelectrochemical water splitting. Nano Lett.9, 2331 (2009). ArticleCASGoogle Scholar

- V. Miikkulainen, M. Leskela, M. Ritala, and R.L. Puurunen: Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys.113, 021301 (2013). ArticleCASGoogle Scholar

- Z. Yin, S. Wu, X. Zhou, X. Huang, Q. Zhang, F. Boey, and H. Zhang: Electrochemical deposition of ZnO nanorods on transparent reduced graphene oxide electrodes for hybrid solar cells. Small6, 307 (2010). ArticleCASGoogle Scholar

- B.J. Choi, D.S. Jeong, S.K. Kim, C. Rohde, S. Choi, J.H. Oh, H.J. Kim, C.S. Hwang, K. Szot, R. Waser, B. Reichenberg, and S. Tiedke: Resistive switching mechanism of TiO2 thin films grown by atomic-layer deposition. J. Appl. Phy.98, 033715 (2005). ArticleCASGoogle Scholar

- J.S. Daubert, J.Z. Mundy, and G.N. Parsons: Kevlar-based supercapacitor fibers with conformal pseudocapacitive metal oxide and metal formed by ALD. Adv. Mater. Interfaces3, 1600355 (2016). ArticleCASGoogle Scholar

- P. Banerjee, W-J. Lee, K-R. Bae, S.B. Lee, and G.W. Rubloff: Structural, electrical, and optical properties of atomic layer deposition Al-doped ZnO films. J. Appl. Phy.108, 043504 (2010). ArticleCASGoogle Scholar

- P. Yang, X. Tong, G. Wang, Z. Gao, X. Guo, and Y. Qin: NiO/SiC nanocomposite prepared by atomic layer deposition used as a novel electrocatalyst for nonenzymatic glucose sensing. ACS Appl. Mater. Interfaces7, 4772 (2015). ArticleCASGoogle Scholar

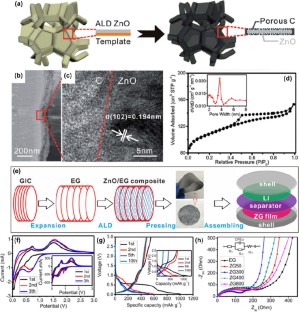

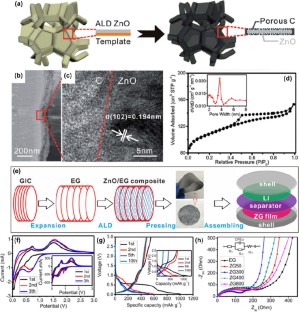

- Y.T. Zhao, G.S. Huang, D.R. Wang, Y. Ma, Z. Fan, Z. Bao, and Y.F. Mei: Sandwiched porous C/ZnO/porous C nanosheet battery anodes with a stable solid-electrolyte interphase for fast and long cycling. J. Mater. Chem. A6, 22870 (2018). ArticleCASGoogle Scholar

- F. Naeem, S. Naeem, Y.T. Zhao, D.R. Wang, J. Zhang, Y.F. Mei, and G.S. Huang: TiO2 nanomembranes fabricated by atomic layer deposition for supercapacitor electrode with enhanced capacitance. Nanoscale Res. Lett.14, 92 (2019). ArticleCASGoogle Scholar

- M. Schindler, S.K. Kim, C.S. Hwang, C. Schindler, A. Offenhaeusser, and S. Ingebrandt: Novel post-process for the passivation of a CMOS biosensor. Phys. Status. Solidi Rapid Res. Lett.2, 4 (2008). ArticleCASGoogle Scholar

- N. Couniot, T. Vanzieleghem, J. Rasson, N. Van Overstraeten-Schloegel, O. Poncelet, J. Mahillon, L.A. Francis, and D. Flandre: Lytic enzymes as selectivity means for label-free, microfluidic and impedimetric detection of whole-cell bacteria using ALD-Al2O3 passivated microelectrodes. Biosens. Bioelectron.67, 154 (2015). ArticleCASGoogle Scholar

- H. Im, N.C. Lindquist, A. Lesuffleur, and S-H. Oh: Atomic layer deposition of dielectric overlayers for enhancing the optical properties and chemical stability of plasmonic nanoholes. ACS Nano4, 947 (2010). ArticleCASGoogle Scholar

- A. Tereshchenko, V. Fedorenko, V. Smyntyna, I. Konup, A. Konup, M. Eriksson, R. Yakimova, A. Ramanavicius, S. Balme, and M. Bechelany: ZnO films formed by atomic layer deposition as an optical biosensor platform for the detection of grapevine virus A-type proteins. Biosens. Bioelectron.92, 763 (2017). ArticleCASGoogle Scholar

- M. Dominik, A. Lesniewski, M. Janczuk, J. Niedziolka-Joensson, M. Holdynski, L. Wachnicki, M. Godlewski, W.J. Bock, and M. Smietana: Titanium oxide thin films obtained with physical and chemical vapour deposition methods for optical biosensing purposes. Biosens. Bioelectron.93, 102 (2017). ArticleCASGoogle Scholar

- I.S. Wang, Y.T. Lin, C.H. Huang, T.F. Lu, C.E. Lue, P. Yang, D.G. Pijanswska, C.M. Yang, J.C. Wang, J.S. Yu, Y.S. Chang, C. Chou, and C.S. Lai: Immobilization of enzyme and antibody on ALD-HfO2-EIS structure by NH3 plasma treatment. Nanoscale Res. Lett.7, 179 (2012). ArticleCASGoogle Scholar

- M. Lee, N. Zine, A. Baraket, M. Zabala, F. Campabadal, R. Caruso, M.G. Trivella, N. Jaffrezic-Renault, and A. Errachid: A novel biosensor based on hafnium oxide: Application for early stage detection of human interleukin-10. Sens. Actuators, B Actuat. B-Chem.175, 201 (2012). ArticleCASGoogle Scholar

- S. Xie, S.I. Choi, N. Lu, L.T. Roling, J.A. Herron, L. Zhang, J. Park, J.G. Wang, M.J. Kim, Z.X. Xie, M. Mavrikakis, and Y. Xia: Atomic layer-by-layer deposition of Pt on Pd nanocubes for catalysts with enhanced activity and durability toward oxygen reduction. Nano Lett.14, 3570 (2014). ArticleCASGoogle Scholar

- P.H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens: Microstructural design of hard coatings. Prog. Mater. Sci.51, 1032 (2006). ArticleCASGoogle Scholar

- C. Marichy, M. Bechelany, and N. Pinna: Atomic layer deposition of nanostructured materials for energy and environmental applications. Adv. Mater.24, 1017 (2012). ArticleCASGoogle Scholar

- B. Zhu, X. Wu, W.J. Liu, H-L. Lu, D.W. Zhang, Z. Fan, and S.J. Ding: High-performance on-chip supercapacitors based on mesoporous silicon coated with ultrathin atomic layer-deposited In2O3 films. ACS Appl. Mater. Interfaces11, 747 (2019). ArticleCASGoogle Scholar

- A. Purniawan, G. Pandraud, T.S.Y. Moh, A. Marthen, K.A. Vakalopoulos, P.J. French, and P.M. Sarro: Fabrication and optical measurements of a TiO2-ALD evanescent waveguide sensor. Sens. Actuators, A188, 127 (2012). ArticleCASGoogle Scholar

- B. Dunn, H. Kamath, and J.M. Tarascon: Electrical energy storage for the grid: A battery of choices. Science334, 928 (2011). ArticleCASGoogle Scholar

- B. Scrosati and J. Garche: Lithium batteries: Status, prospects and future. J. Power Sources195, 2419 (2010). ArticleCASGoogle Scholar

- J.L. Wang, J. Yang, C.R. Wan, K. Du, J.Y. Xie, and N.X. Xu: Sulfur composite cathode materials for rechargeable lithium batteries. Adv. Funct. Mater.13, 487 (2003). ArticleCASGoogle Scholar

- D. Kundu, E. Talaie, V. Duffort, and L.F. Nazar: The emerging chemistry of sodium ion batteries for electrochemical energy storage. Angew. Chem., Int. Ed.54, 3431 (2015). ArticleCASGoogle Scholar

- J. Fu, Z.P. Cano, M.G. Park, A. Yu, M. Fowler, and Z. Chen: Electrically rechargeable zinc-air batteries: Progress, challenges, and perspectives. Adv. Mater.29, 1604685 (2017). ArticleCASGoogle Scholar

- S.Y. Lang, R.J. Xiao, L. Gu, Y.G. Guo, R. Wen, and L.J. Wan: Interfacial mechanism in lithium–sulfur batteries: How salts mediate the structure evolution and dynamics. J. Am. Chem. Soc.140, 8147 (2018). ArticleCASGoogle Scholar

- N. Nitta, F. Wu, J.T. Lee, and G. Yushin: Li-ion battery materials: Present and future. Mater. Today18, 252 (2015). ArticleCASGoogle Scholar

- Z.P. Cano, D. Banham, S. Ye, A. Hintennach, J. Lu, M. Fowler, and Z.W. Chen: Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy3, 279 (2018). ArticleGoogle Scholar

- M.Q. Snyder, S.A. Trebukhova, B. Ravdel, M.C. Wheeler, J. DiCarlo, C.P. Tripp, and W.J. Desisto: Synthesis and characterization of atomic layer deposited titanium nitride thin films on lithium titanate spinel powder as a lithium-ion battery anode. J. Power Sources165, 379 (2007). ArticleCASGoogle Scholar

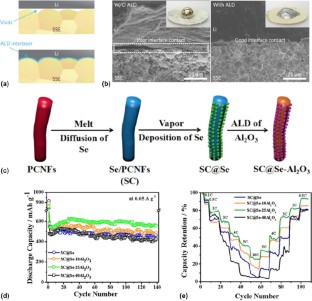

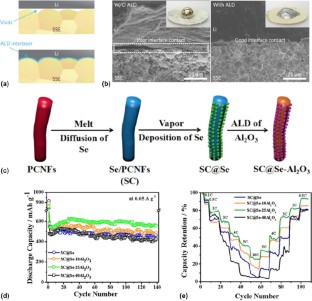

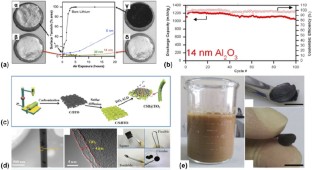

- D.T. Ma, Y.L. Li, J.B. Yang, H.W. Mi, S. Luo, L.B. Deng, C.Y. Yan, P.X. Zhang, Z.Q. Lin, X.Z. Ren, J.Q. Li, and H. Zhang: Atomic layer deposition-enabled ultrastable freestanding carbon-selenium cathodes with high mass loading for sodium–selenium battery. Nano Energy43, 317 (2018). ArticleCASGoogle Scholar

- X. Han, Y. Gong, K. Fu, X. He, G.T. Hitz, J.Q. Dai, A. Pearse, B.Y. Liu, H. Wang, G. Rubloff, Y.F. Mo, V. Thangadurai, E.D. Wachsman, and L.B. Hu: Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat. Mater.16, 572 (2017). ArticleCASGoogle Scholar

- J. Wolfenstine, J.L. Allen, J. Read, and J. Sakamoto: Chemical stability of cubic Li7La3Zr2O12 with molten lithium at elevated temperature. J. Mater. Sci.48, 5846 (2013). ArticleCASGoogle Scholar

- S. Hy, Y.H. Chen, H.M. Cheng, C.J. Pan, J.H. Cheng, J. Rick, and B.J. Hwang: Stabilizing nanosized Si anodes with the synergetic usage of atomic layer deposition and electrolyte additives for Li-ion batteries. ACS Appl. Mater. Interfaces7, 13801 (2015). ArticleCASGoogle Scholar

- E. Kazyak, K.H. Chen, K.N. Wood, A.L. Davis, T. Thompson, A.R. Bielinski, A.J. Sanchez, X. Wang, C.M. Wang, J. Sakamoto, and N.P. Dasgupta: Atomic layer deposition of the solid electrolyte garnet Li7La3Zr2O12. Chem. Mater.29, 3785 (2017). ArticleCASGoogle Scholar

- C. Guan, X.L. Li, H. Yu, L. Mao, L.H. Wong, Q.Y. Yanc, and J. Wang: A novel hollowed CoO-in-CoSnO3 nanostructure with enhanced lithium storage capabilities. Nanoscale6, 13824 (2014). ArticleCASGoogle Scholar

- J. Jiang, J. Luo, J. Zhu, X. Huang, J. Liu, and T. Yu: Diffusion-controlled evolution of core–shell nanowire arrays into integrated hybrid nanotube arrays for Li-ion batteries. Nanoscale5, 8105 (2013). ArticleCASGoogle Scholar

- M.P. Yu, J.S. Ma, H.Q. Song, A.J. Wang, F.Y. Tian, Y.S. Wang, H. Qiua, and R.M. Wang: Atomic layer deposited TiO2 on a nitrogen-doped graphene/sulfur electrode for high performance lithium-sulfur batteries. Energy Environ. Sci.9, 1495 (2016). ArticleCASGoogle Scholar

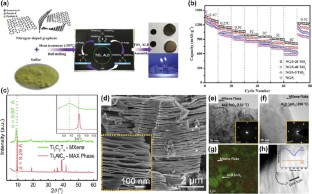

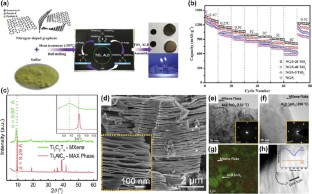

- B. Ahmed, D.H. Anjum, Y. Gogotsi, and H.N. Alshareef: Atomic layer deposition of SnO2 on MXene for Li-ion battery anodes. Nano Energy34, 249 (2017). ArticleCASGoogle Scholar

- M. Xie, X. Sun, S.M. George, C. Zhou, J. Lian, and Y. Zhou: Amorphous Ultrathin SnO2 Films by Atomic layer deposition on graphene network as highly stable anodes for lithium-ion batteries. ACS Appl. Mater. Interfaces7, 27735 (2015). ArticleCASGoogle Scholar

- Y.L. Li, Y.T. Zhao, G.S. Huang, B.R. Xu, B. Wang, R.B. Pan, C.L. Men, and Y.F. Mei: ZnO nanomembrane/expanded graphite composite synthesized by atomic layer deposition as binder-free anode for lithium ion batteries. ACS Appl. Mater. Interfaces9, 38522 (2017). ArticleCASGoogle Scholar

- J.B. Goodenough and Y. Kim: Challenges for rechargeable Li batteries. Chem. Mater.22, 587 (2010). ArticleCASGoogle Scholar

- D.T. Ma, Y.L. Li, J.B. Yang, H.W. Mi, S. Luo, L.B. Deng, C.Y. Yan, M. Rauf, P.X. Zhang, X.L. Sun, X.Z. Ren, J.Q. Li, and H. Zhang: New strategy for polysulfide protection based on atomic layer deposition of TiO2 onto ferroelectric-encapsulated cathode: Toward ultrastable free-standing room temperature sodium-sulfur batteries. Adv. Funct. Mater.28, 1705537 (2018). ArticleCASGoogle Scholar

- M.P. Yu, A.J. Wang, F.Y. Tian, H.Q. Song, Y.S. Wang, C. Li, J.D. Hongd, and G.Q. Shi: Dual-protection of a graphene-sulfur composite by a compact graphene skin and an atomic layer deposited oxide coating for a lithium–sulfur battery. Nanoscale7, 5292 (2015). ArticleCASGoogle Scholar

- Y.W. Zhu, S. Murali, M.D. Stoller, K.J. Ganesh, W.W. Cai, P.J. Ferreira, A. Pirkle, R.M. Wallace, K.A. Cychosz, M. Thommes, D. Su, E.A. Stach, and R.S. Ruoff: Carbon-based supercapacitors produced by activation of graphene. Science332, 1537 (2011). ArticleCASGoogle Scholar

- G.A. Snook, P. Kao, and A.S. Best: Conducting-polymer-based supercapacitor devices and electrodes. J. Power Sources196, 1 (2011). ArticleCASGoogle Scholar

- P. Simon and Y. Gogotsi: Materials for electrochemical capacitors. Nat. Mater.7, 845 (2008). ArticleCASGoogle Scholar

- A.G. Pandolfo and A.F. Hollenkamp: Carbon properties and their role in supercapacitors. J. Power Sources157, 11 (2006). ArticleCASGoogle Scholar

- L. Wei, M. Sevilla, A.B. Fuertes, R. Mokaya, and G. Yushin: Hydrothermal carbonization of abundant renewable natural organic chemicals for high-performance supercapacitor electrodes. Adv. Energy Mater.1, 356 (2011). ArticleCASGoogle Scholar

- X.L. Chen, L.B. Qiu, J. Ren, G.Z. Guan, H.J. Lin, Z.T. Zhang, P.N. Chen, Y.G. Wang, and H.S. Peng: Novel electric double-layer capacitor with a coaxial fiber structure. Adv. Mater.25, 6436 (2013). ArticleCASGoogle Scholar

- S. Bose, T. Kuila, A.K. Mishra, R. Rajasekar, N.H. Kim, and J.H. Lee: Carbon-based nanostructured materials and their composites as supercapacitor electrodes. J. Mater. Chem.22, 767 (2012). ArticleCASGoogle Scholar

- T. Sruthi and T. Kartick: Route to achieving enhanced quantum capacitance in functionalized graphene based supercapacitor electrodes. J. Phys.: Condens. Matter31, 47 (2019). Google Scholar

- S.P. Liu and X.X. Pan: An aqueous hybrid supercapacitor employing honeycomb-shaped MoS2 nanosheets as anode. J. Nanosci. Nanotechnol.20, 1020 (2020). ArticleCASGoogle Scholar

- Y. Feng, Y. Li, W. Yang, and H. Huang: Facile synthesis of nickel cobalt layered double hydroxide nanosheets intercalated with sulfate anion for high-performance supercapacitor. J. Nanosci. Nanotechnol.20, 1260 (2020). ArticleCASGoogle Scholar

- M. Fan, B. Ren, X. Yang, H. Yu, and L. Wang: NiO@NiO and NiO@Co3O4 hollow core/shell composites for high-performance supercapacitor electrodes. J. Nanosci. Nanotechnol.19, 7785 (2019). ArticleCASGoogle Scholar

- C. Guan, X. Qian, X. Wang, Y. Cao, Q. Zhang, A. Li, and J. Wang: Atomic layer deposition of Co3O4 on carbon nanotubes/carbon cloth for high-capacitance and ultrastable supercapacitor electrode. Nanotechnology26, 094001 (2015). ArticleCASGoogle Scholar

- J.S. Daubert, N.P. Lewis, H.N. Gotsch, J.Z. Mundy, D.N. Monroe, E.C. Dickey, M.D. Losego, and G.N. Parsons: Effect of meso- and micro-porosity in carbon electrodes on atomic layer deposition of pseudocapacitive V2O5 for high performance supercapacitors. Chem. Mater.27, 6524 (2015). ArticleCASGoogle Scholar

- P. Ripka and M. Janosek: Advances in magnetic field sensors. IEEE Sens. J.10, 1108 (2010). ArticleGoogle Scholar

- B. Lee, S. Roh, and J. Park: Current status of micro- and nano-structured optical fiber sensors. Opt. Fiber Technol.15, 209 (2009). ArticleCASGoogle Scholar

- E.W. Hill, A. Vijayaragahvan, and K. Novoselov: Graphene sensors. IEEE Sens. J.11, 3161 (2011). ArticleCASGoogle Scholar

- S.T. Han, H. Peng, Q. Sun, S. Venkatesh, K.S. Chung, S.C. Lau, Y. Zhou, and V.A.L. Roy: An overview of the development of flexible sensors. Adv. Mater.29, 1700375 (2017). ArticleCASGoogle Scholar

- D. Zhang, K. Zhang, Y.L. Yao, X.H. Xia, and H.Y. Chen: Multilayer assembly of prussian blue nanoclusters and enzyme-immobilized poly(toluidine blue) films and its application in glucose biosensor construction. Langmuir20, 7303 (2004). ArticleCASGoogle Scholar

- M. Chikae, T. Fukuda, K. Kerman, K. Idegami, Y. Miura, and E. Tamiya: Amyloid-beta detection with saccharide immobilized gold nanoparticle on carbon electrode. Bioelectrochemistry74, 118 (2008). ArticleCASGoogle Scholar

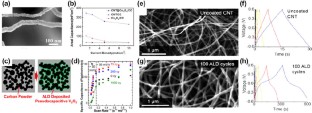

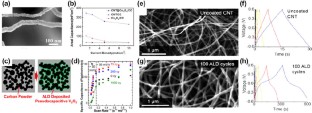

- T. Choi, S.H. Kim, C.W. Lee, H. Kim, S-K. Choi, S-H. Kim, E. Kim, J. Park, and H. Kim: Synthesis of carbon nanotube-nickel nanocomposites using atomic layer deposition for high-performance non-enzymatic glucose sensing. Biosens. Bioelectron.63, 325 (2015). ArticleCASGoogle Scholar

- C. Zhang, B. Huang, L. Qian, S. Yuan, S. Wang, and R. Chen: Electrochemical biosensor based on nanoporous Au/CoO core–shell material with synergistic catalysis. ChemPhysChem17, 98 (2016). ArticleCASGoogle Scholar

- L. Wu, G. Wan, S. Shi, Z. He, X. Xu, Y. Tang, C. Hao, and G. Wang: Atomic layer deposition-assisted growth of CuAl LDH on carbon fiber as a peroxidase mimic for colorimetric determination of H2O2 and glucose. New J. Chem.43, 5826 (2019). ArticleCASGoogle Scholar

- H. Cha, J. Lee, L.R. Jordan, S.H. Lee, S.H. Oh, H.J. Kim, J. Park, S. Hong, and H. Jeon: Surface passivation of a photonic crystal band-edge laser by atomic layer deposition of SiO2 and its application for biosensing. Nanoscale7, 3565 (2015). ArticleCASGoogle Scholar

- C. Wang, Q. Fu, X. Wang, D. Kong, Q. Sheng, Y. Wang, Q. Chen, and J. Xue: Atomic layer deposition modified track-etched conical nanochannels for protein sensing. Anal. Chem.87, 8227 (2015). ArticleCASGoogle Scholar

- A. Purniawan, P.J. French, G. Pandraud, and P.M. Sarro: TiO2 ALD nanolayer as evanescent waveguide for biomedical sensor. Procedia Eng.5, 1131 (2010). ArticleCASGoogle Scholar

- D.J. Comstock, S.T. Christensen, J.W. Elam, M.J. Pellin, and M.C. Hersam: Tuning the composition and nanostructure of Pt/Ir films via anodized aluminum oxide templated atomic layer deposition. Adv. Funct. Mater.20, 3099 (2010). ArticleCASGoogle Scholar

- X. Du and S.M. George: Thickness dependence of sensor response for CO gas sensing by tin oxide films grown using atomic layer deposition. Sens. Actuators, B135, 152 (2008). ArticleCASGoogle Scholar

- A.J. Niskanen, A. Varpula, M. Utriainen, G. Natarajan, D.C. Cameron, S. Novikov, V.M. Airaksinen, J. Sinkkonen, and S. Franssila: Atomic layer deposition of tin dioxide sensing film in microhotplate gas sensors. Sens. Actuators, B148, 227 (2010). ArticleCASGoogle Scholar

- D.J. Yun, G.H. Seo, W.H. Lee and S.M. Yoon: Improvement in Sensing Responses to Ammonia Gas for Gas Sensors With Separately Designed Sensing Element Using ALD-Grown ZnO Nanoparticles and Read-Out Element of Top-Gate In-Ga-Zn-O Thin-Film Transistor IEEE Transactions on Electron Devices64, 2350 (2017). ArticleCASGoogle Scholar

- C. Han, X. Li, C. Shao, X. Li, J. Ma, X. Zhang, and Y. Liu: Composition-controllable p-CuO/n-ZnO hollow nanofibers for high-performance H2S detection. Sens. Actuators, B285, 495 (2019). ArticleCASGoogle Scholar

- Y.T. Lin, C.S. Huang, L. Chow, J.M. Lan, C.M. Yang, L.B. Chang, and C.S. Lai: Light-immune pH sensor with SiC-based electrolyte-insulator-semiconductor structure. Appl. Phys. Express6, 127002 (2013). ArticleCASGoogle Scholar

- M.H. Jakob, S. Gutsch, C. Chatelle, A. Krishnaraja, J. Fahlteich, W. Weber, and M. Zacharias: Flexible thin film pH sensor based on low-temperature atomic layer deposition. Phys. Status. Solidi Rapid Res. Lett.11, 1700123 (2017). ArticleCASGoogle Scholar

- L. Wang, L. Li, T. Zhang, X. Liu, and J.P. Ao: Enhanced pH sensitivity of AlGaN/GaN ion-sensitive field effect transistor with Al2O3 synthesized by atomic layer deposition. Appl. Surf. Sci.427, 1199 (2018). ArticleCASGoogle Scholar

- Q.L. Guo, Y.T. Zhao, G. Wang, D. Chen, H.N. Zhao, C.M. Jiang, G.S. Huang, Z.F. Di, and Y.F. Mei: Sponge-templated production of ultra-thin ZnO nanosheets for printed ultraviolet photodetectors. Appl. Phy. Lett.115, 122106 (2019). ArticleCASGoogle Scholar

- Y.T. Zhao, G.S. Huang, Y.L. Li, R. Edy, P. Gao, H. Tang, Z. Bao, and Y.F. Mei: Three-dimensional carbon/ZnO nanomembrane foam as an anode for lithium-ion battery with long-life and high areal capacity. J. Mater. Chem. A6, 7227 (2018). ArticleCASGoogle Scholar

Acknowledgments

This work was supported by the Natural Science Foundation of China (Nos. 61975035 and U1632115), Science and Technology Commission of Shanghai Municipality (No. 17JC1401700), the National Key R&D Program of China (Nos. 2017YFE0112000 and 2015ZX02102-003), and the Program of Shanghai Academic Research Leader (19XD1400600).